Do You Have A Concrete Project We Can Help With?

Mudjacking vs Polyurethane Concrete Raising

To address the problem of sinking, sagging, or unlevel concrete, home and business owners have two main options available to them: mudjacking or polyurethane concrete raising.

It’s not always obvious what the pros and cons of each are, which is why the concrete professionals at AAA Concrete Raising are here to help.

What Are These Techniques, Exactly?

Let’s start by defining our terms, here.

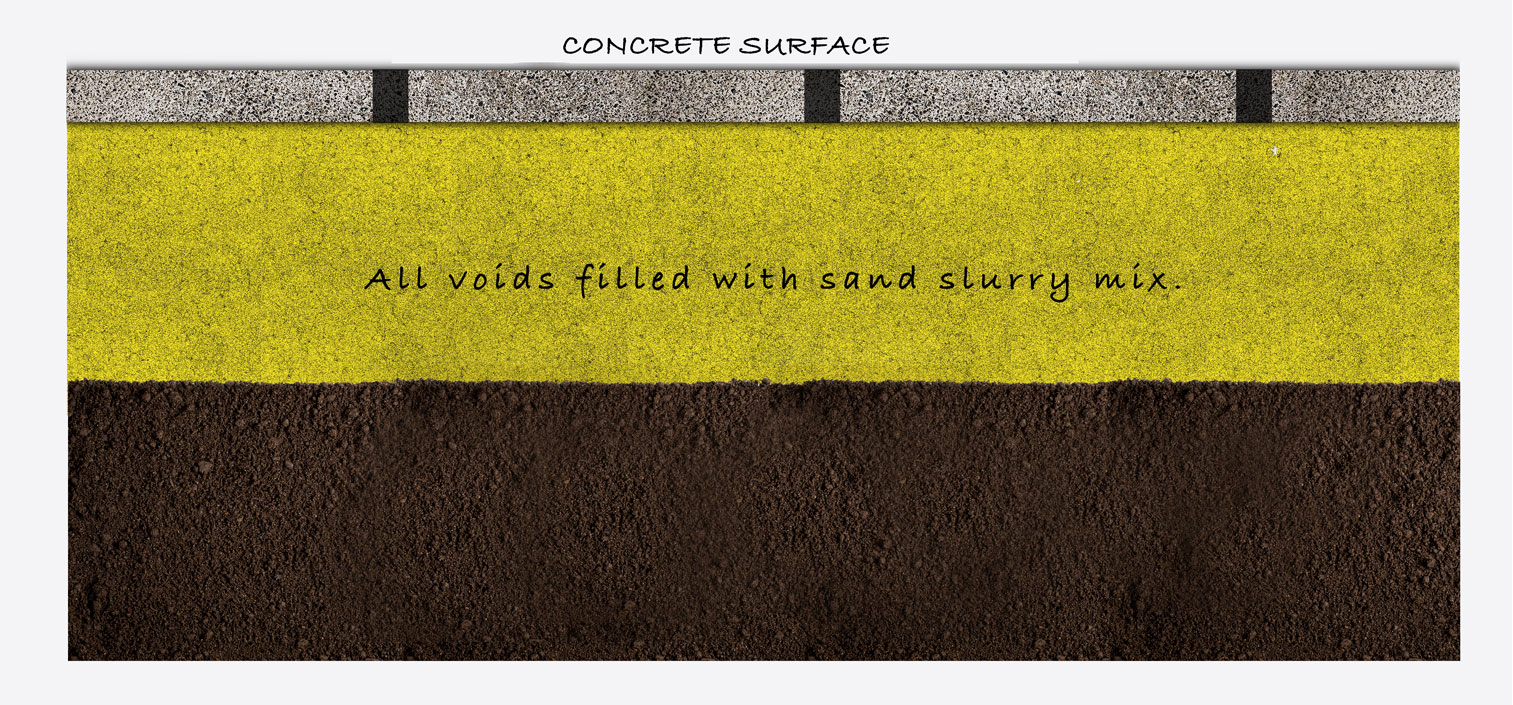

‘Mudjacking’ refers to the injection of a sand slurry mix into the unsupported area that sits just below the concrete. This unsupported area is often riddled with voids and pockets of varied densities, and mudjacking has traditionally been highly effective at filling these voids with material that can withstand the weight and pressure from above.

‘Polyurethane Concrete Raising’, also known as ‘Sprayed Polyurethane Foam’, uses similar steps and tools to add support to the area below the concrete, but there’s an important difference between PCL and Mudjacking: PCL uses a synthetic foam substance that expands after it is injected.

Mudjacking, on the other hand, relies on a natural substance (mostly sand and water) that doesn’t contain any harmful, man-made chemicals.

When to Opt for Polyurethane Concrete Raising

James Warner, a recognized expert in the field of structural support engineering, has authored numerous academic publications on the subject of using a polyurethane-based substance to raise concrete.

Mr. Warner has conducted thorough research into the pros and cons of this technique, and his conclusion is as follows:

“There are several limitations to poly foam raising, the greatest of which is probably lack of complete cavity filling.”

This does not mean that there are not suitable applications for the use of polyurethane injections to support unlevel concrete slabs.

Example: Foot traffic 24/7 in a hotel lobby. One example of a case where using spray foam injections can be beneficial is when the continued use of the surface concrete is more important than filling all the voids to stabilize the slab for many years to come.

AAA Concrete Raising has been involved in hundreds of concrete raising projects throughout the years, and we’ve encountered very few instances where the use of polyurethane is preferable to the use of sand slurry.

So, while there are numerous benefits to using PCL, there are often more benefits to using traditional mudjacking to accomplish the same goal of effectively raising and stabilizing the affected concrete.

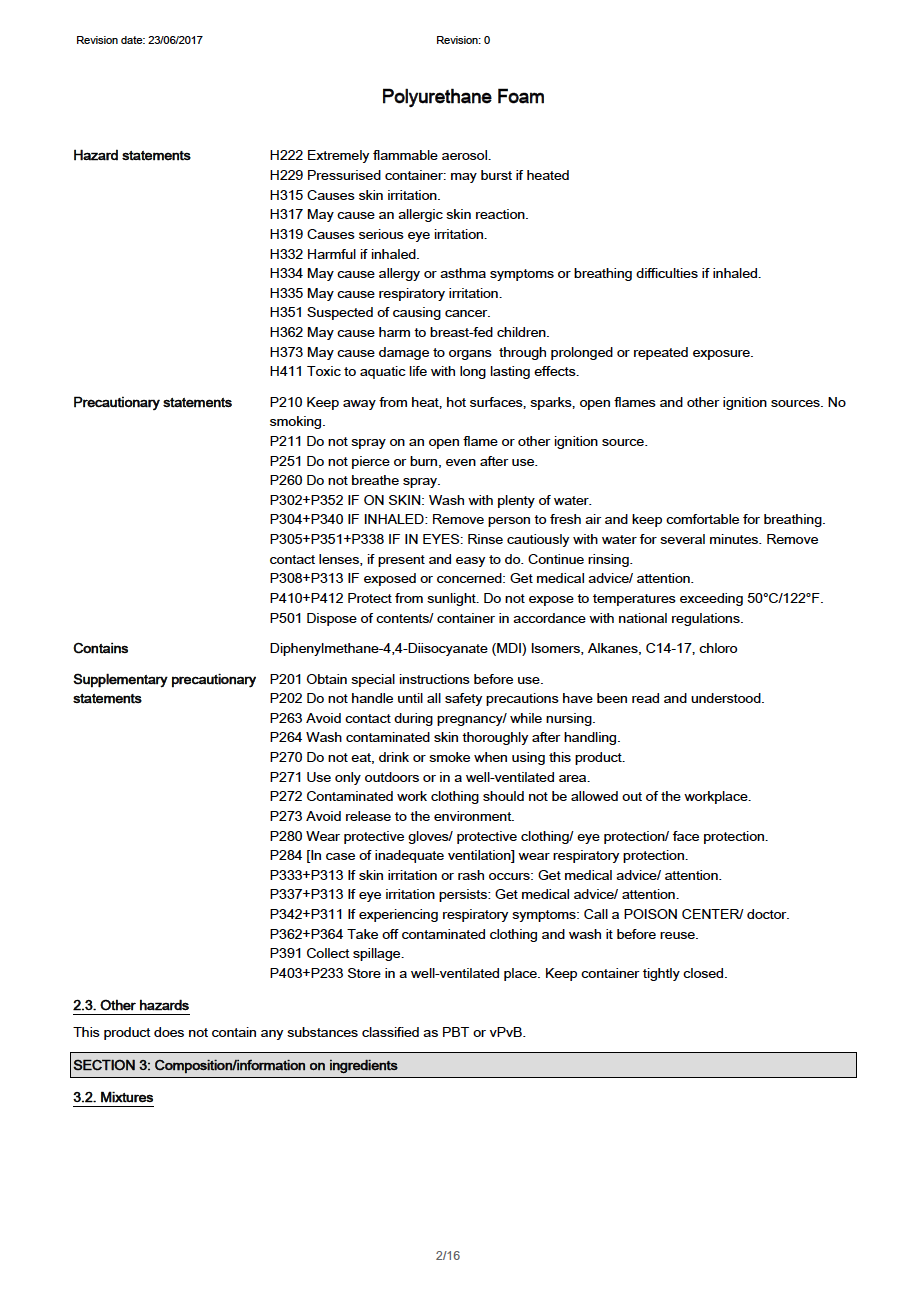

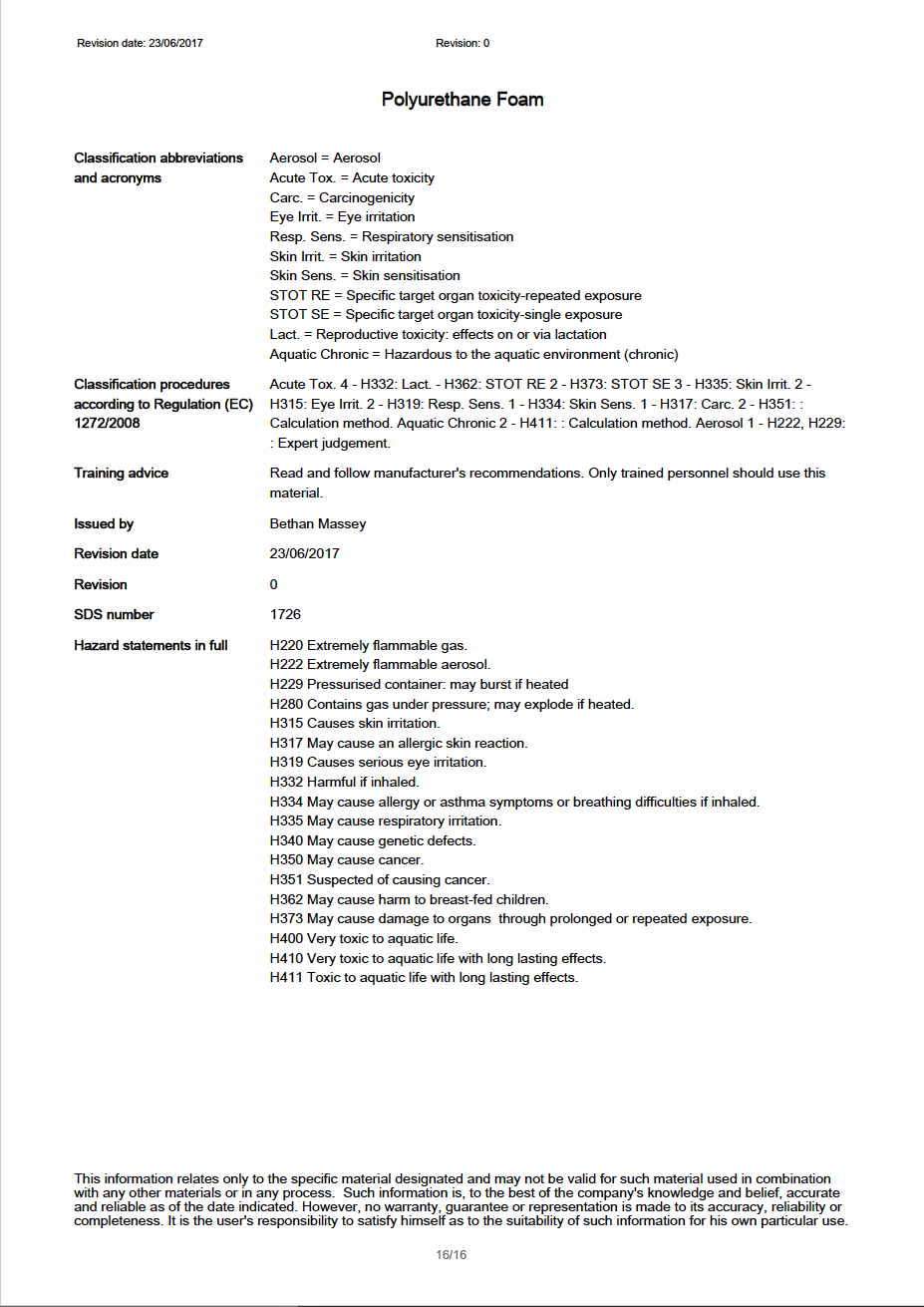

There are numerous hazards associated with the use of polyurethane foam, which can be found in more detail below:

MSDS REFERENCED FROM http://docs-europe.electrocomponents.com/webdocs/07c3/0900766b807c383b.pdf.

When to Opt for Mudjacking

Mudjacking winds up being the more sensible choice for most concrete raising projects, across-the-board. The reasons for this are threefold:

1. Mudjacking is safer for laborers and the environment. The Environmental Protection Agency (EPA) has issued a public notice that speaks directly to the potentially harmful additives that can be included in polyurethane injection materials.

Their statement is as follows:

Granting this, mudjacking is the safer and more environmentally responsible choice.

2. Mudjacking is more effective at completely filling subsurface voids. When polyurethane foam is injected, it will expand to fill a specific area. Then, it will stop, and it will harden.

This limits the ability of polyurethane to completely support the concrete above, making mudjacking a more effective solution in most cases.

3. Mudjacking is better for long-term concrete stability and support. Because more voids are filled using a sand slurry, and because this slurry doesn’t harden over time like polyurethane does, mudjacking provides more long-term support for the concrete.

After considering all of the pros and cons associated with both of these concrete raising techniques, the verdict is clear: mudjacking remains the superior solution to remediate lowered or unlevel concrete.

However, not all mud jacking contractor companies are created equal.

The AAA CONCRETE RAISING DIFFERENCE

Don’t risk your concrete raising project to a fly-by-night concrete contractor who leaves the job site half-finished. Contact AAA Concrete Raising today and inquire about a free estimate. We’ll take the time to explain your options, answer all of your questions, and perform a quality concrete raising job that will exceed your expectations.

To get started, contact us today by calling (303) 526-2222.

View PDF

View PDF